Capabilities

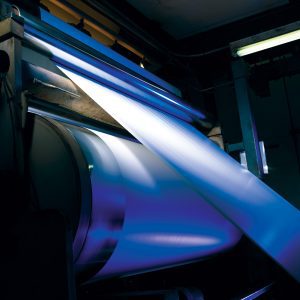

Our coater enables us to operate at maximum efficiency and we are equipped to run order quantities as small or large as needed.

We provide full-service quality assurance testing, with component traceability for each coating batch developed and/or roll coated.

Coater “Dual Mayer Rod Coating Application”

- Width 22″ – 81.5″

- Max Diameter In: 51″

- Core ID In: 3″, 4″, 5″, 6″

- 2 Ovens; each with 3 independently controlled zones — for flexible drying options

- 2 Coating stations with turn bars and back sprayers in line for custom coating configurations

- Double Coated 1 Side

- Double Coated 1 Side with back treatment

- Coated 2 sides

- Inline Corona Treatment — both sides up to 66″ wide

- Inline Calender: 30″– 81.5″

Rewinder “Ellington” (Drum)

- Width: 12″ – 90″

- Max Diameter In: 70″

- Max Diameter Out: 58″ or 6,600#

- Min Diameter Out: 13″

- Min Slit Width: 6″ (Max 7 slit rolls)

- Core ID In: 3″, 4″, 5″, 6″

- Core ID Out: 3″, 4″, 5″, 6″, 8″, 10″, 12″

Rewinder “Cameron” (Duplex)

- Width 19″ – 81.5″

- Max Diameter In: 60″

- Max Diameter Out: 45″ or 2,500# (per shaft)

- Min Slit Width: 2″ (Max 25 slit rolls)

- Core ID In: 3″, 4″, 5″, 6″

- Core ID Out: 3″, 6″

Quality Lab

Fully equipped QA testing capabilities in real time

- Basis Weight

- Brightness

- Caliper

- Cobb

- COF

- Color (L*a*b*)

- Gloss

- Hercules Sizing

- Moisture

- Opacity

- Porosity

- Scrub Resistance

- Smoothness

- Stiffness

- Tear

- Tensile

- Whiteness

- Custom Testing Available

- Quality assurance at every step

- Complete traceability of raw materials to finished product

Research & Development

Experts creating custom formulations to meet your needs.

- PHD Chemist

- Drawdown Machine

- Samples for evaluation

- Trials & Scaleups

- Color Matching

- Custom Testing Methods

We are well known and respected for our technical capabilities and manufacturing agility. We take pride in providing highly responsive and personal customer service.